- Call Us

+91 - 7972068414 / 9819877192

- Send Mail

response@shantaengineering.com

Shore Hardness Tester (Durometer)

Shore Hardness Tester (Durometer)

The range of durometers is widely used to test the hardness of soft materials. The instrument can be either hand held or fitted to an optional stand for increased repeatability. The range of Shore Durometers encompasses a number of hardness values.

Features:

- • Easy to use with immediate results.

- • Standard test for material hardness.

- • High repeatability.

Conforms To:

ASTM D 2240, BS 7442-3.2, DIN 53505, FIAT 50411, ISO 868, ISO 7267-2, NF T51-123. Supply with: Shore Durometer, operating instructions, Check Piece.

A round point indents the material under a fixed force spring and the hardness is displayed on the dial in Shore Hardness Units.

Range : 0 to 100 Shore

Resolution : 2 Shore.

Indenter : Truncated cone

Model : SHRT - I

A round point indents the material under a fixed force spring and the hardness is displayed on the dial in Shore Hardness Units.

Features:

Range : 0 to 100 Shore

Resolution : 1 Shore

Indenter : Truncated cone

Model : DSHT - III

Shore Durometer A with Max indicator

The spring loaded outer ring assures a constant measuring pressure and eliminates false readings due to difference between operators.

This ensures a constant pressure and prevents measuring errors

Adjustable max. indicator marks to highlight working range of the hardness tester.

Features:

Range : 0 to 100 Shore

Resolution : 1 Shore

Indenter : Truncated cone

Model : DSHT - II

A round point indents the material under a fixed force spring and the hardness is displayed on the Digital in Shore Hardness Units.

Features:

Range : 0 to 100 Shore

Resolution : 1 Shore

Indenter : Truncated cone

Operating Key : ON/ OFF& Zero./Re Set

Zero setting at any position

Power Supply : 1.5V LR 44 battery

Model : DSHT IV

Yuzuki,

The principle used to measure hardness is based on measuring the resistance force of the penetration of a pin into the test material under a known spring load. The amount of penetration (max. 2.54 mm / 0.1 in.) is converted to hardness reading on a scale with 100 units.

Features:

Material Type : stainless steel

Size : 7 cm x 5 cm x 5 cm

Included Components : 1 Tester Shore D with Pin Pointer

Shore A : RHTEA

Shore D : RHTPPD

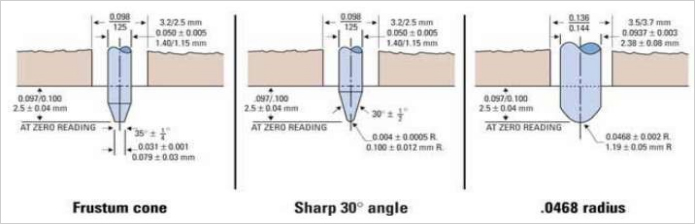

| Shore | Application | Max. Force | Indenter |

|---|---|---|---|

| A | For soft, flexible rubber, plastic, PVC, polyester, neoprene, leather, Thiokol, nitril rubbers, tyres, etc. | 821 g | Frustum cone |

| B | Same as A scale for high values | 821 g | Sharp 30° Angle |

| C | Same as D scale for low values | 4533 g | Frustum cone |

| D | Scale for hard and rigid surfaces synthetic materials, acrylics, plexi-glass, printing rolls, cellulose, acetates, densified wood, nylon | 4533 g | Sharp 30° Angle |

| DO | Same as B and C | 4533 g | 0.0468 radius |

| O | Same as A scale for low values | 821 g | 0.0468 radius |

| OO | For sponge, natural rubber, silicone | 113 g | 0.0468 radius |

Stand For Durometer

Specially designed Stands are used to improve the accuracy and reproducibility of both analog and digital durometer hardness tester readings by ensuring that the presser foot is exactly parallel to the specimen table. Any analog or digital durometer can be mounted on an applicable operating stand. The operating stand is primarily intended for use on a test specimen with parallel sides. Irregularly shaped objects may be tested in a nest or a fixture to make the given surface parallel to the durometer presser foot. ASTM D 2240 specifies three categories of operating stands: Type 1 are basic, manual operating stands. Type 2 is stands capable of controlling the rate of descent. Type 3 are hydraulically, pneumatically or electromechanical driven. Stands that fall into all three categories. For assistance in selecting the proper operating stand to fit your durometer.

Model is subject to change without notice.