- Call Us

+91 - 7972068414 / 9819877192

- Send Mail

response@shantaengineering.com

Universal Tensile Testing Machine - Twin Column

Universal Tensile Testing Machine - Twin Column

Shanta Engineering Universal Testing Machines are electro mechanical machines with digital display of load & displacement & pulley belt system for changing speeds. The machines are designed for testing various materials like rubber, plastics, cables, leather, paper, plywood and metals. Tension, compression, bend and flexural tests can be performed on these machines with suitable grips and fixtures. The machines are powder coated for elegant look. The critical components are plated for rust prevention and durability.

Main Features :

- ❖ Selection of different speeds by pulley belt system.

- ❖ Facility to mount different load cells.

- ❖ Facility to mount various grips / fixtures for different tests and materials like rubber, plastics, cables, leather, paper, plywood and metals.

Electronic Control Panel :

- ❖ Front panel membrane type keyboard for test set up.

- ❖ 7 segment digital display of load and displacement.

- ❖ Storage of important parameters such as peak load, braking load and max. displacement.

- ❖ Facility to return of crosshead to home position for next test.

Note :

- ❖ Over load & over travel protection is standard.

- ❖ Lower capacity load cells can be used with any machine for better load resolution.

- ❖ Grips can be selected from wide range available for different application.

Special Options :

- ❖ Load cells of different capacities are available as optional items.

- ❖ Displacement resolution of 0.1 mm is optional.

- ❖ Compression, Bending & flexural attachment to suit specific tests is available as optional.

- ❖ A.C. Variable speed is available as optional.

- ❖ P.C. interface is optional.

UNIVERSAL TENSILE TESTING MACHINE WITH PLC BASED AVAILABLE IN DIFFERENT CAPACITIES.

ASTM D638

Advantage of PLC :

- ❖ Speed range of 0.1mm/min to 500mm/min.

- ❖ Speed accuracy of ± 1%.

- ❖ Operation through touch pad HMC of 7 inch size.

- ❖ Easy to operate.

- ❖ Load counts of 20000.

- ❖ Higher load sampling frequency each.

- ❖ Reading /10 milliseconds.

- ❖ Facility to control program through computer.

All results such as peak load, elongation at Peak load, Break load, elongation at break load, %elongation at Peak, %elongation at break, Tensile strength at peak, Tensile strength at Break, Flexural stress, Compression strength, Secant Modulus, Tangent Modulus, and Flexural Modulus are directly displayed or Microcontroller as well as through PC software.

SPECIFICATIONS UTM TWIN COLUMN FOR VARIABLE SPEED

| MODEL NO. | SET-T 5000 N | SET-T 10 KN | SET-T 20 KN | SET-T 30 KN |

| Max. capacity(Kg) | 500 | 1000 | 2000 | 3000 |

| Load Resolution(N) 1:10,000 | 0.5 | 1.0 | 2.0 | 2.0 |

| Max. crosshead displacement without grips/fixtures (mm)> | 900 | 900 | 900 | 900 |

| Diisplacement resolution (mm) | 0.2 | 0.2 | 0.2 | 0.2 |

| Column clearance(mm) | 380 | 380 | 450 | 450 |

| Variable speed with the help of A.C.Drive | 5mm/min to 100mm/min or 30mm/min to 500mm/min | |||

| Variable speed with the help of A.C.Servo Drive | 1mm/min to 500mm/min | |||

| Machine Dimensions w x d x h in (mm ) | 1100 x 330 x 1800 | 1100 x 330 x 1800 | 1100 x 400 x 1800 | 1100 x 400 x 1800 |

| Power requirement for A.C. Drive | 0.5 HP | 1.0 HP | 2.0 HP | 2.0 HP |

| Power requirement for A.C. Servo Drive | 400W | 600W | 1.0KW | 1.0KW |

| Power Supply | 230 VAC±10%, Single Phase, 50Hz with Neutral & Earth | |||

Grip And Fixtures :

The following Grips and Fixtures can be supplied as per order :

- ❖ Grips for flat and round specimen with different inserts.

- ❖ Vice type grips.

- ❖ Pneumatic grips.

- ❖ Fixture for bend test / flexural test.

- ❖ Sheat test attachment.

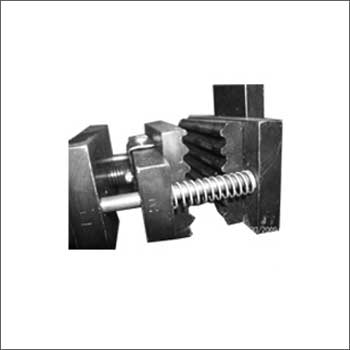

GRIPS

1. SEG 5.1 For dumbell shape specimen of PVC, rubber and polyethylene Inserts knurling.

Max. Specimen size - 35 mm wide x 4 mm thk.

2. SEG 5.2 For strips of PVC Rubber and polyester films. Inserts with rubber lining.

Max. Strip Size - 50 mm wide X 4 mm thk

3. SEG 5.3 For plywood and asbestos. Inserts with fine knurling.

Max. Specimen size = 100 mm wide X 4 mm thk

4. SEG 5.4 For rigid metal wire (1.0 mm dia to 6.0 mm dia )

5. SEG 5.5 For rigid metal strips inserts with knurling.

Max. Strips size = 15 mm wide x 6 mm thk

6. SEG 5.6 For flexible metal wires 20 SWG and finer.

7. SEG 5.7 For flexible rubber cords between 10 to15 mm dia.

SPECIFICATIONS UTM TWIN COLUMN FIXED SPEED BELT / PULLEY SYSTEM

| MODEL NO. | SET-T-5000N | SET-T-10KN | SET-T-20KN | SET-T-30KN | SET-T-50KN |

| Max.Capacity(Kg) | 500 | 1000 | 2000 | 3000 | 5000 |

| Load Resolution(N) 1:10000 |

0.5 | 1.0 | 2.0 | 3.0 | 5.0 |

| Max. crosshead displacement without grips/fixtures (mm) | 900 | 900 | 900 | 900 | 900 |

| Displacement resolution (mm) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Column Clearance (mm) | 380 | 380 | 450 | 450 | 450 |

| Test Speed (mm/min) | 50, 100, 250 & 500 | 30, 50 & 100 | 30, 50 & 100 | 30, 50 & 100 | 30, 50 & 100 |

| Machine Dimensions W x D x H |

1100 x 325 x 1800 | 1100 x 325 x 1800 | 1100 x 400 x 1800 | 1100 x 400 x 1800 | 1100 x 400 x 1800 |

| Power Requirement | 0.5 HP | 1.0 HP | 2.0 HP | 2.0 HP | 3.0 HP |

| Power Supply | 415VAC±10%, 3 Phase, 50 Hz with Neutral & Earth | ||||